Imagine this scenario: You have booked your container, secured space on a vessel, and coordinated your inland logistics..

Everything appears to be on track—until you receive a costly notification that your container has been classified as overweight.. Penalties are imminent, shipment delays are likely, and your customer is already asking questions..

This is not an uncommon story in the world of containerised shipping.. At the heart of many such incidents lies one core issue—failure to declare accurate cargo weight..

Let us unpack why declaring the correct weight matters, when a container is considered overweight, and the very real consequences of getting it wrong..

The basics: Why cargo weight accuracy is critical

Accurate weight declaration is not just a best practice—it is a legal requirement, a safety protocol, and a commercial necessity..

When shippers or consolidators declare the wrong weight (either accidentally or deliberately), they risk disrupting not just their own shipment but also broader port, terminal, and vessel operations..

Here is why:

- Vessel stability: Ship planners rely on declared container weights to calculate stowage plans. Inaccurate weights can cause an imbalance, jeopardising the ship’s trim, stability, and even seaworthiness..

- Crane safety: Port cranes are designed for specific weight tolerances.. Misdeclared containers risk equipment damage, crane shutdowns, or even operator injury..

- Road and rail limits: Many countries enforce strict axle weight limitations.. A container exceeding legal road weight limits may be rejected at the port or pulled over by authorities en route..

- Insurance implications: Incorrect weight declarations can lead to denied claims in case of damage or loss..

In short, what may seem like a minor oversight can trigger a domino effect of safety violations, regulatory fines, and commercial losses..

When is a container considered overweight..??

Understanding when a container becomes “overweight” is not always as straightforward as it seems.. There are three overlapping—but often misunderstood—definitions that shippers need to navigate:

- Container Payload Limit

Every container has a maximum payload, the maximum weight it can safely carry, excluding its own tare weight..

Every legal container has a valid safety approval plate called CSC (Container Safety Convention) plate in order for it to be used in international trade.. This is in accordance with the provisions of the International Convention on Safe Containers of 1972..

This CSC plate confirms that the container has been inspected and found to be suitable for transportation on board the ship.

This plate has all the details of the Owners, Technical Data, and ACEP information.. ACEP being short for, Approved Continuous Examination Programme, in short every 30 months a container must be turned into a Container Depot for examination.. Read more about it in the Anatomy of a Shipping Container..

This CSC plate also shows the gross weight as can be seen in an example below..

Using the above plate as an example, a container that has been loaded more than the allowed weight, in this case 32,500 kgs including the tare weight of the container, will be considered as OVER WEIGHT..

It is therefore imperative that the packing warehouse/depot check this CSC plate upon the arrival of the container and ensure that they do not exceed the Maximum Gross Weight mentioned on the plate..

Most container shipping lines have containers that have different weight capacities because not all cargoes are heavy.. Therefore, if the shipper is aware that his cargo is going to be heavy, say Minerals, Steel Coils, or similar types, they can always request the shipping line to release such “heavy tested” or “high payload” containers for packing such cargoes..

- Gross Vehicle Weight (GVW) on Roads

Even if your cargo is within the container’s payload limit, it may still be legally overweight for road transport..

Each country has its own road weight limits based on axle count, vehicle configuration, and road infrastructure.. For example:

- In South Africa, a truck and container combination typically has a legal road limit of 36,000 kg to 44,000 kg depending on the number of axles..

- In the USA, federal limits restrict the GVW to 80,000 lbs (36,287 kg) without special permits..

So, even if your cargo fits comfortably inside the container, you may not be able to move it legally by truck unless you obtain special clearance or reconfigure your transport strategy.. Liaise with your transporter to understand the weight limitations in our city, country and ensure that it is not exceeded..

- Terminal and Vessel Handling Limits

Some port terminals or feeder vessels impose their own lift or handling restrictions, especially in older or constrained ports.. These can range from 27 tonnes to 32 tonnes gross weight, depending on crane type and berth structure..

A container above these limits may be refused at gate-in or rolled to another vessel that can accommodate it..

The VGM regulation and its role

In response to the growing risks of misdeclared weights, the IMO introduced the Verified Gross Mass (VGM) regulation under SOLAS (Safety of Life at Sea) in 2016..

This regulation mandates that every export container must have its gross weight verified and communicated to the carrier before loading..

There are two permissible methods for obtaining VGM:

- Weighing the packed container, including dunnage and securing materials..

- Calculating weight based on individual items and packaging materials, then adding the container tare..

Failure to submit a valid VGM can lead to a container being held back at the port, missing its intended vessel, and incurring storage, demurrage, and repositioning costs..

Consequences of non-compliance

Still wondering if this really happens in the real world..?? Here are a few tangible examples even after the implementation of VGM requirements..

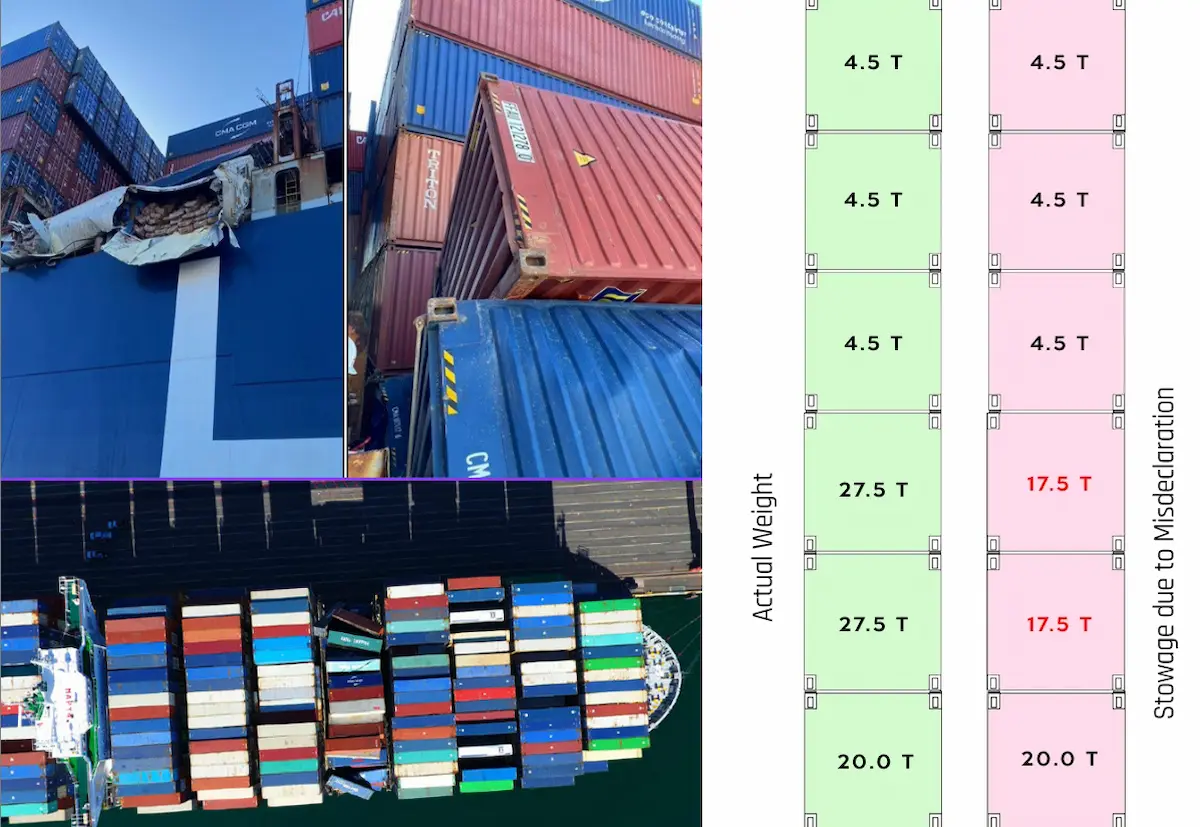

MAIB and NTSB investigation reports on CMA CGM Washington and President Eisenhower respectively, show damages and claims due to factors including weight misdeclarations..

The National Transportation Safety Board determines that “the probable cause of the container loss aboard the containership President Eisenhower was the input of incorrect cargo weight for 39 containers when the cargo loading plan was developed by shoreside planners, resulting in the containers being loaded in overweight and reverse-stratified stacks, causing cargo-securing equipment to fail while the vessel was drifting.”

“It is most likely that its collapse was initiated following the structural failure of one of its containers, brought about by a combination of factors including: excessive stack loads as a result of mis-stowed or overweight containers;” – part of MAIB’s conclusion on the investigation of CMA CGM Washington..

These are not isolated incidents—they are frequent, costly, and largely avoidable with proper diligence..

Practical steps for all stakeholders

It is the joint responsibility of the shipper, the packing warehouse, the transporter, and the shipping line to ensure that the weight of the container does not exceed the maximum allowed limits in the interest of everyone’s safety..

Here are some steps every exporter, forwarder, agent and trucker should follow:

- Know your container’s payload and tare weight—refer to the CSC plate or your container provider.. Read the markings on the container door, which provide ALL information about the container..

- Weigh your cargo using calibrated equipment, not estimates or assumptions..

- Understand your country’s and the destination country’s legal road limits, especially when planning cross-border moves..

- Submit the VGM on time—and retain records in case of audit or dispute..

- Consider your entire logistics chain, including terminal, rail, and inland haulage restrictions..

Being thorough at the start avoids major problems later down the chain..

Conclusion: The truth about weight is non-negotiable

In an industry that revolves around precision, predictability, and compliance, getting the cargo weight right is not optional—it is essential..

Whether you are a BCO shipping high-value machinery or a freight forwarder moving consolidated cargo, understanding the mechanics of container weights, VGM regulations, and road limitations can save you from operational snags, legal complications, and reputational damage..

Weight misdeclaration is more than a paperwork issue or red tape, it is a matter of safety, cost, and credibility.. Declare it right the first time, and your shipment (and your business) will thank you for it..

This article has been republished after some critical updates..