Innovation is not always about the latest app, AI engine, or cutting-edge software.. In shipping and logistics, we have been innovating for decades, often in very practical ways that change the way goods move and value flows..

During a recent discussion on “Cross Industry Global Network – Rethinking Collaboration for a Sustainable Future” by Lagertha Join Forces, we chatted about Open Innovation..

One clear theme emerged: the best breakthroughs occur when “market needs intersect with real-world problem solvers” and that technology is just one part of that story..

Henry Chesbrough, who coined the term Open Innovation, defines it as “the use of purposive inflows and outflows of knowledge to accelerate internal innovation, and expand the markets for external use of innovation, respectively.”

In simpler terms, open innovation means sharing ideas and knowledge across companies and industries to solve problems faster and better, rather than keeping everything in-house..

Innovation is older than we think

When we talk about innovation today, minds often jump to AI, IoT, and data analytics.. One of the examples of open innovation I used in the discussion was the development of modern Ro-Ro ships..

Before Ro-Ro ships, cars were mostly loaded into holds individually using cranes, a slow and damage-prone process.. Between the 1950s and 1960s, specialized car carriers transformed automotive shipping by allowing vehicles to be driven directly onto the ship, replacing the crane-based loading and discharging, dramatically improving speed, safety, and efficiency..

Ro-Ro ships didn’t emerge from one company’s lab, they were shaped by knowledge exchange between carmakers (the customer), port designers (the infrastructure), and shipping lines (the delivery mechanism)..

This cross-industry feedback loop is a classic example of open innovation.. The inflow of market needs from the automotive sector drove the outflow of design knowledge from the maritime sector..

The same mindset fuels today’s advances.. Innovation begins when someone says, “this way is too slow, too costly, or too risky, how can we do it better?”

Customer demand drives today’s breakthroughs

Modern shipping faces new demands: perishables must arrive fresh, automotive assembly lines cannot stop, and supply chains must remain resilient.. Smart containers and IoT sensors have stepped into this space, giving unprecedented visibility to both shippers and receivers..

These connected devices monitor temperature, humidity, shock and even unauthorised openings.. If a container carrying fresh fruit experiences a two-degree variance for 24 hours, an alert goes out..

If a shock event occurs, say a drop or hard impact, it is logged, flagged and reported.. If light penetrates the container mid-voyage, indicating potential theft or tampering, the system warns immediately..

For perishable goods exporters, importers, or traders, it can mean saving a shipment and preserving brand reputation..

Technology alone is not enough

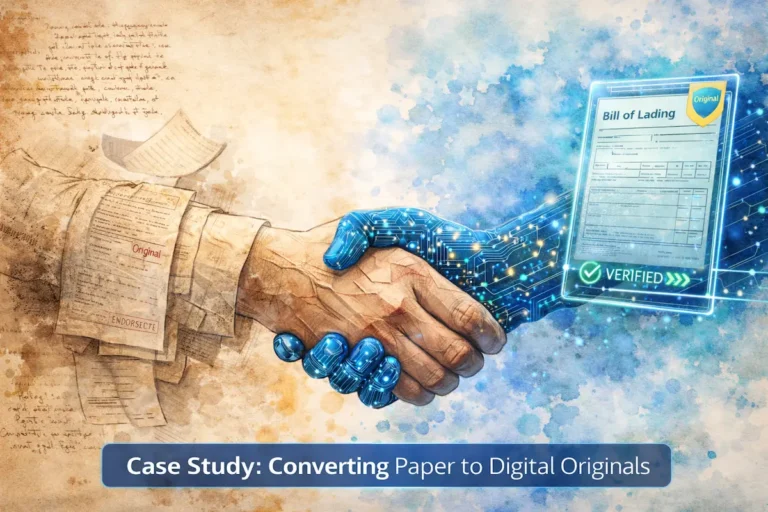

Yet there is a caution in this story.. As technology accelerates, there is a risk that new entrants into the industry rely too heavily on digital tools without fully understanding the underlying operations and risks..

Innovation can make us comfortable, even complacent.. Some professionals assume that if a device or AI system reports something, it must be true.. But technology is only as good as the data fed into it.. AI can be wrong; IoT can fail; dashboards can mislead when context is missing..

Trust is earned, not automatic..

That is why experienced practitioners remain essential.. Deep domain experts bring decades of hard-won insights about how vessels, cargoes, and contracts work..

They know what red flags to watch for and what “normal” looks like.. Pairing that expertise with new tools creates innovation that is both smart and safe..

Technology isn’t the enemy, it’s the amplifier.. But without context, even the smartest system can misfire..

Who is training the trainer..??

AI learns from the data it is given.. If we, as an industry, feed poor-quality or incomplete information, the answers coming back will be flawed..

New professionals who rely on AI without understanding its blind spots risk costly mistakes.. Asking the hard questions like “Who trained this system? What data sits behind it? What bias might exist?” is now part of being innovative..

This reinforces the importance of collaboration: technologists, data providers, freight operators, compliance specialists, and veteran shipping professionals working together.. True open innovation is not just “crowdsourcing ideas”, it is building trust across disciplines to create solutions that work in the unpredictable real world of trade..

Moving forward: a balanced view of innovation

Open innovation in shipping is not new, but it is evolving.. The lesson is clear:

- Start with the problem, not the tech. Ask what customers and markets actually need, whether that is faster loading, safer reefer cargo, or transparent risk data..

- Blend experience with technology. The best results come when industry veterans and digital natives work side by side..

- Question the source. Tools like AI are powerful but not infallible; verify before you act..

- Collaborate widely. Real breakthroughs often come when different sectors share insights, from mining to automotive to perishable logistics..

Innovation is a moving target.. From roll-on/roll-off carriers to smart containers and AI-enabled analytics, shipping’s history proves we are capable of transformation.. But the future belongs to those who marry digital capability with deep operational wisdom..